Project abstract

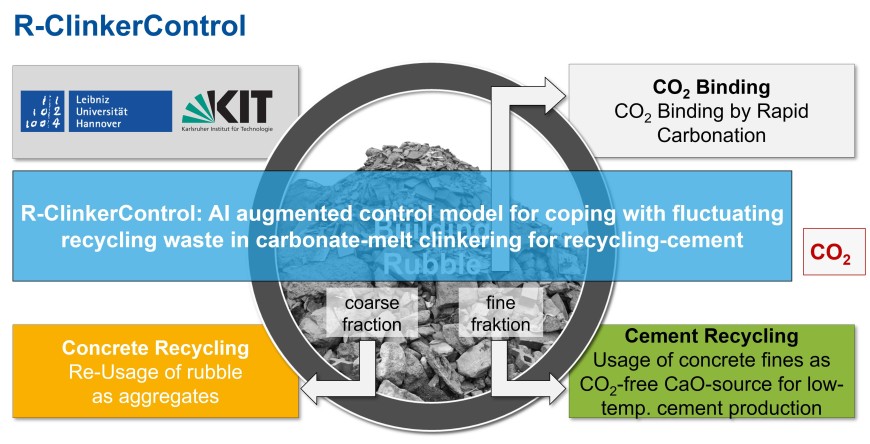

Overview Synthesizing high-C2S cement clinker at reduced temperatures (<1000 °C) could significantly cut CO₂ emissions compared to ordinary Portland cement (OPC). Mineralizing agents like Na₂CO₃ and CaCl₂, combined with a high (>90%) CO₂ concentration in kiln gas, significantly accelerate reaction rates by forming carbonate melts, which improve CaO dissolution and clinker phase development. In-situ X-ray diffraction (XRD) studies indicate that C₂S formation begins at 650 °C and completes below 1000 °C. These lower temperatures enable the use of electric heating with renewable energy. Adding CaCO₃ can help compensate for the low calcium/silica (C/S) ratios in mixed construction waste (MCW). However, the mechanisms of melt formation in the low-temperature carbon-melt cement clinker and the impact of impurities in MCW on clinker synthesis require further investigation.

Project Goals This project aims to develop a scalable, low-temperature carbon-melt process (<1000 °C) for synthesizing CO₂-minimized “R-cements” from MCW as a carbon-free raw meal. It will address challenges posed by the natural variability in MCW’s chemical composition and physical properties by using sensor-driven, machine-learning process controls to stabilize cement quality.

Objectives

- MCW Composition Analysis:

Assess typical MCW compositions, including crushed concrete, masonry, glass, and sulfates, identifying variations in elemental composition and implications for clinker synthesis. This includes setting chemical boundaries for using MCW as a clinker raw meal, supplementary cementitious material (SCM), or filler, while devising strategies for handling each main type of MCW (e.g., calcareous or siliceous).

- Low-Temperature Clinker Synthesis:

Study clinker synthesis routes at 600-1000 °C using MCW with minimal lime content, accounting for its highly variable composition and minor impurities. Focus on synthesizing clinker in a CO₂-saturated environment, forming calcium-sodium carbonate melts to enhance reaction kinetics and C2S phase development. The study will also explore spurrite as an intermediate mineral phase.

- Performance Evaluation of Clinkers:

Analyze fresh and hardened cement pastes containing synthesized clinkers to assess rheology, mechanical properties, and durability. Strategies to mitigate property fluctuations will include adjustments to clinker granulometry, use of accelerators, and superplasticizers. The interaction of R-clinker with other SCMs will also be studied to build a performance database for machine-learning models.

- Holistic Control Model Development:

Integrate data from previous objectives into a control model that maximizes MCW use in eco-friendly binders while ensuring consistent technical performance and minimal CO₂ emissions. The model will establish optimized raw meal compositions and clinkering conditions for different MCW streams and countermeasures for variations, such as CaCO₃ additions for silica-rich feeds.

Applicants: Michael Haist, Prof. Dr.-Ing. and Peter Stemmermann, Dr. rer. nat.